Cranfield’s green hydrogen demonstrators

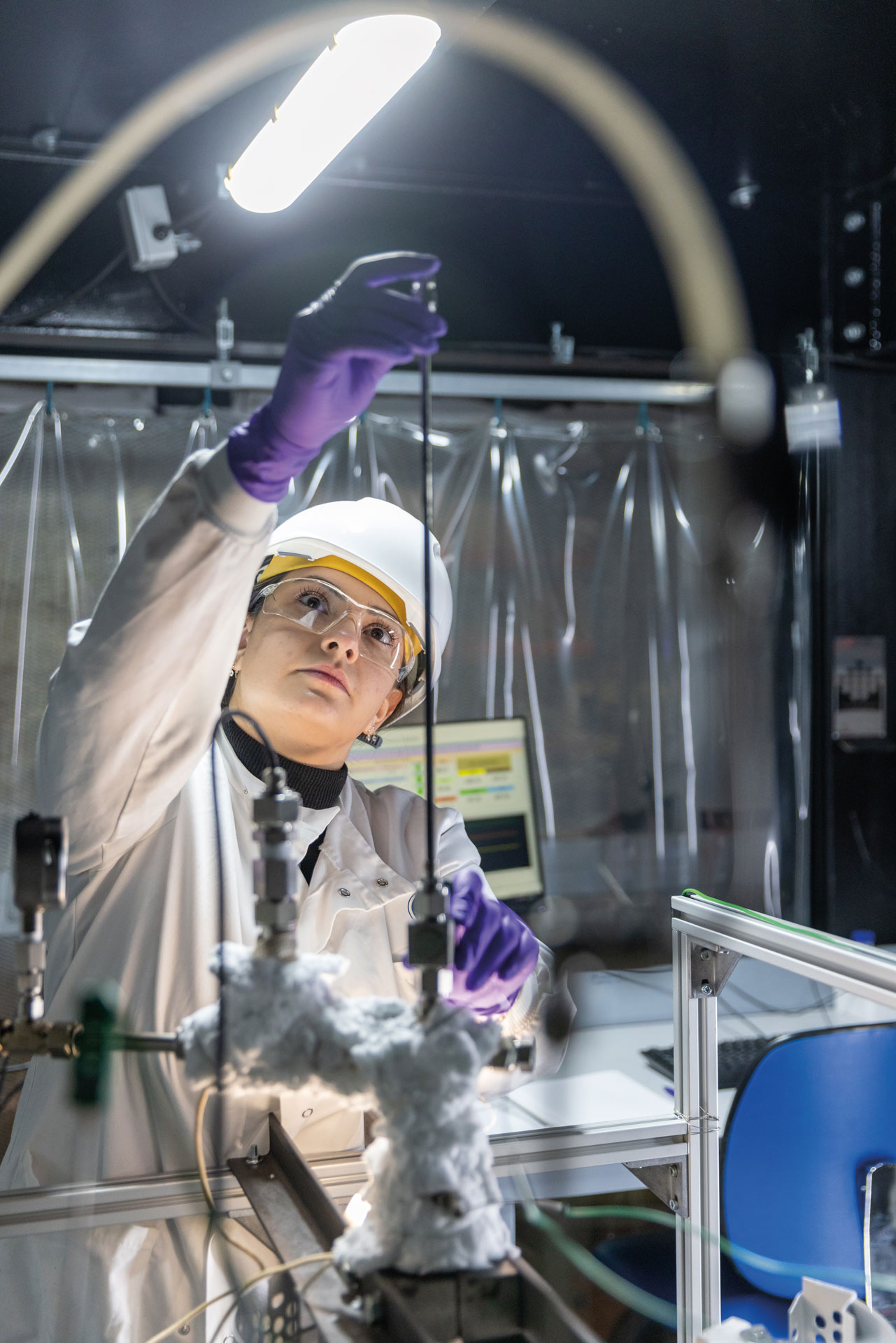

Cranfield’s Hydrogen Research Network and the HyPER project is exploring bulk hydrogen production by Sorbent Enhanced Steam Reforming (SESR)

Home to the Hydrogen Research Network and the HyPER project, Cranfield University is exploring bulk hydrogen production by Sorbent Enhanced Steam Reforming (SESR), as well as catalytic methane cracking. SESR can produce higher purity, lower carbon and lower cost hydrogen from natural gas than conventional technologies. In addition, researchers at Cranfield are exploring potential end-user opportunities for the carbon by-product with manufacturers.

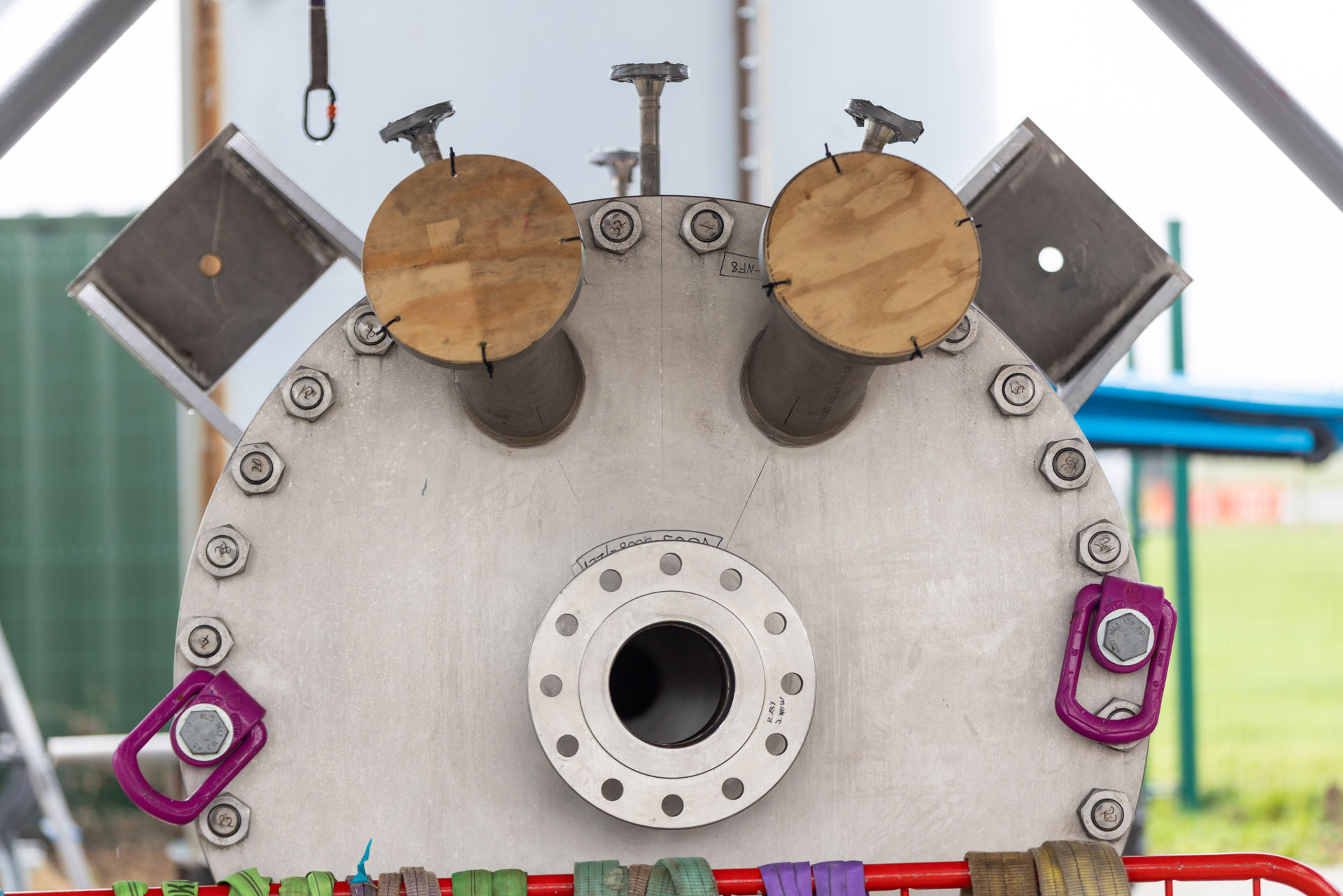

The HyPER demonstrator

The HyPER demonstrator can produce hundreds of kg of H2 per day. It is a megawatt scale pilot facility that utilises sorbent enhanced reforming to generate clean H2.

This pilot scale facility can be used by businesses as a test bed for their equipment either integrated into or around the facility.

The demonstrator can be of use to any business developing anything from H2/CO2 leak detection, gas analysis, pipe fittings/gaskets, non-destructive testing and evaluation of metals/pipes, new instrumentation, new metal alloys, gas compressors, gas purification systems, and more. Cranfield welcomes engagement from businesses interested in scaling up and installing clean H2 production facilities at their sites.

If you are interested in finding out more about the HyPER demonstrator, please contact

Dr Peter Clough

Centre for Renewable and Low Carbon Energy, Cranfield University.

Email: p.t.clough@cranfield.ac.uk

The Turquoise Hydrogen demonstrator

The Turquoise Hydrogen demonstrator consists of a central upright fixed fluidised bed reactor which generates hydrogen from methane, with built in mechanisms for heating and heat recovery. In the reactor, methane molecules are split into their constituents, H2 and carbon. This pilot reactor has an in-built system to separate gaseous H2 and remove the solid carbon, with a projected minimum hydrogen output of ~ 6 kg/day. In order to reduce the cost of hydrogen (per kg), we currently exploit the by-product solid carbon in batteries, water and air purification, soil-based crop enhancement products, magnetic applications.

The pilot reactor will be made available as a test bed for production of low carbon hydrogen. This will be particularly beneficial to businesses that use carbon as feedstocks, for example manufacturing and product development for batteries, supercapacitors, water purification, air purification, electronics, ink formulations.”

To find out more about the Turquoise Hydrogen demonstrator, please contact:

Professor Upul Wijayantha

Professor and Head of the Centre for Renewable and Low Carbon Energy

Email: upul.wijayantha@cranfield.ac.uk